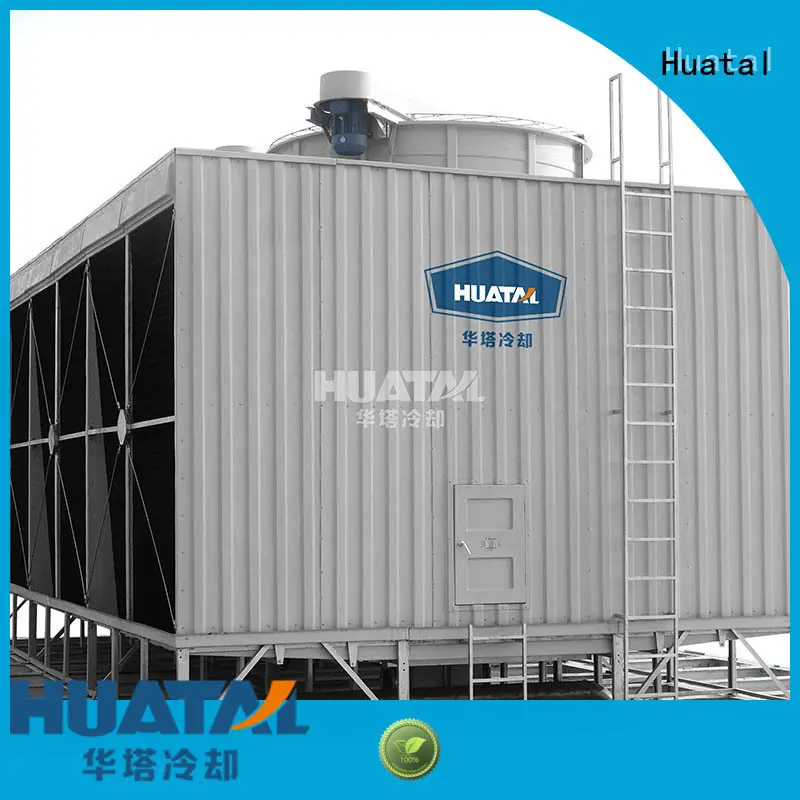

Huatal - Closed Cooling Tower Manufacturer & Industrial Cooling Tower Solution Provider

Huatal factory price for freezing

1. Huatal cooling tower capacity has a professional design. It is designed by specialists who master the fundamentals of designing the most commonly used parts, elements, and units of various machines.

2. Advanced quality testing equipment and methods are used to ensure high quality products.

3. The product performance is reliable, durable, welcomed by users.

4. Jiangsu Huatal Cooling Technology Co., Ltd. has the abundant research, development and manufacturing capacity.

Company Features

1. Jiangsu Huatal Cooling Technology Co., Ltd. has always been focusing on the R&D and production of .

2. We have a team of quality assurance specialists. They have a consistent track record for maintaining high standards of excellence in the production of products.

3. Looking forward to the future, our company will as always, pursue excellence and innovation. We will earn more customers relying on our innovative and high-quality products. We have adopted a sustainable production approach that is responsible for our environment. This approach has significantly decreased the waste amount.

Applications: This product is widely used in cement, mineral processing, electronics, chemicals, food processing, metallurgy, casting, carbon materials, machining, timber building materials and other industries.

Working principle Introduction: Dust gas enters the middle and lower enclosures through the air inlet of the precipitator. The dust and gas are separated through the filter of the filter bag. Dust is adsorbed on the surface of the filter bag, and clean air is discharged from the air outlet through the filter bag. Increasing the amount of dust deposited on the surface of the filter bag over time is increasing. According to the procedure set by the pulse blower, the pulse blow valve triggers on in sequence. Compressed air inside the air bag is instantly blown out from each hole of the injection pipe and sprayed into the corresponding filter bag via the venturi. The dust adsorbed on the surface of the filter bag then falls off into the hopper and is discharged through the discharge valve Directly into the warehouse.

QUICK LINKS

PRODUCTS

CONTACT US