Product features

HBW closed countercurrent cooling tower

◆ Imported POSCO Zinc Magnesium Aluminum Alloy Coated Plate with outstanding anti-corrosion effect. The service life is around 10-20 times of normal galvanized plate, the surface coating has fluidity, with cut protection (automatic healing).

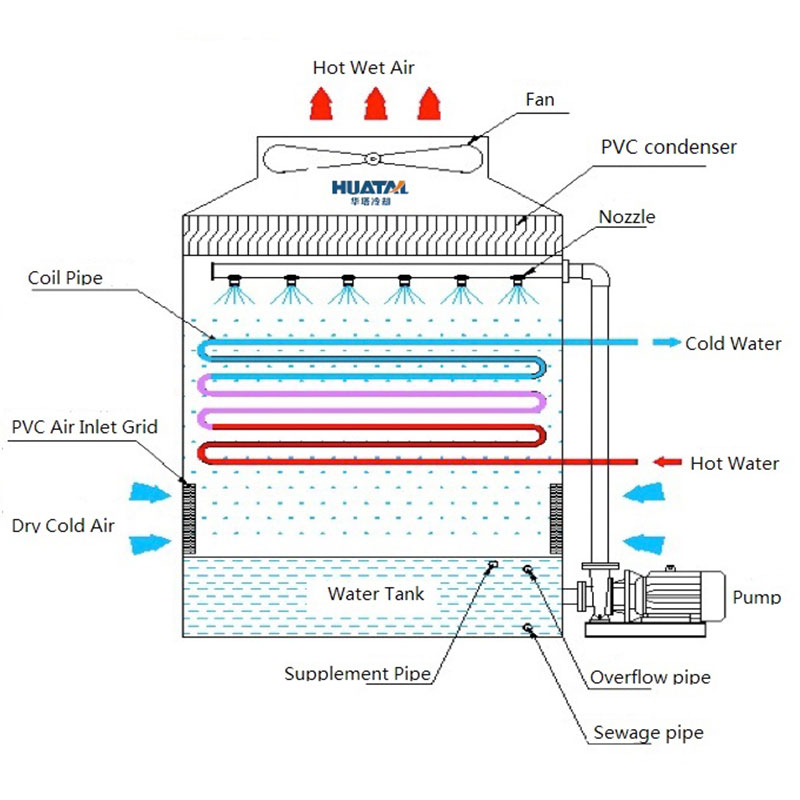

◆ Counter flow cooling system, less heat dissipation blind zone, high heat exchange efficiency;

◆ The effective dehydrator features extremely low drifting ratio;

◆ The product adopts anti-freeze and energy-saving design to ensure the circulating water drain and avoid frost damage when the temperature is low in the northern region.

◆ Unit design beautiful and generous, automatic digital display, easy operation and maintenance.

◆ HBW counter flow closed cooling tower is suitable for various industries, such as casting, forging, air compressor, die casting machine, injection molding machine, electric furnace, water-cooled screw machine, etc…

◆ HBW counter flow closed cooling tower, compact tower structure, small floor space; high air inlet efficiency on both four sides; large heat dissipation area of the coil pipe, not easy to scale; small pressure loss inside the coil pipe, less system energy consumption; Good anti-freezing performance, suitable for cold zone region; spray water circulation system with ice melting device to reduce winter maintenance costs;

Product features

HBW closed countercurrent cooling tower

◆ HBW counter flow closed cooling tower, equipped with automatic digital display temperature control device, intelligent control of fan and spray pump start and stop, saving energy and environmental protection.

◆ HBW counter flow closed cooling tower, structural parts and outside plate adopts imported magnesium aluminum zinc alloy coated plate, or 304 stainless steel; imported motor; high air bucket, large air volume and low noise fan; special spray pump for evaporative cooling only; large water volume and low lift; ABS nozzle has patent certificate, and spray evenly; The coil pipe has the patent certificate, the pipe length is long, the pressure loss is small, the flow rate is controlled at 2.1m/s. The coil pipe can adopts T2 deacidified red copper, or 304/316 stainless steel, it depends on clients’ customized requirements.

◆ HBW counter flow closed cooling tower can be designed as tandem stepped type cooling tower, the inlet temperature of the cooling tower can reach 55℃~95℃;

◆ HBW counter flow closed cooling tower with unique air inlet design, suitable for deserts, plateaus and high dust regions.

◆ The design flow rate of HBW counter flow closed cooling tower is from 5m³/h to 500m³/h. It has strong versatility and can also be spliced to meet the needs of all walks of life.

◆ HBW counter flow closed cooling tower can meet customers' customized requirements and design and produce according to customers' specific needs.

HBW series coil pipe minimum water flow chart | |

Type | (Liters /per sec) |

HBW-10A、10B、10C、10D | 1.4-5.6 |

HBW-12A、12B、12C | 6.9-9.7 |

HBW-15A、15B、17A | 11.1-18 |

HBW-21A、21B、21C、21D、21E、21F、21G、21H | 19.4-48.6 |

HBW-26A、26B、26C | 55.6-69.4 |

Type | Finished Size(mm) | Pneumatic system | Spray pump | Interface pipe diameter(mm) | Weight | ||||||||

Tota length(L) | Length(L1) | Width (W) | Height (H) | Power (kw) | Air Volume (m3/h) | Power (Kw) | Water yield (m3/h) | Inlet and outlet pipe | Overflow outlet Sewage outlet | Supplement water pipe | Net weight (Kg) | Operating weight (Kg) | |

HBW-10A | 2200 | 1000 | 1000 | 1830 | 0.55 | 8400 | 0.75 | 20 | DN50 | DN40 | DN25 | 450 | 700 |

HBW-10B | 2400 | 1220 | 1000 | 1900 | 0.55 | 8400 | 0.75 | 20 | DN50 | DN40 | DN25 | 490 | 800 |

HBW-10C | 2300 | 2000 | 1020 | 1830 | 0.55*2 | 16800 | 0.75 | 20 | DN65 | DN40 | DN25 | 460 | 1000 |

HBW-10D | 2300 | 2000 | 1020 | 1900 | 0.55*2 | 16800 | 0.75 | 20 | DN65 | DN40 | DN25 | 500 | 1050 |

HBW-12A | 2860 | 2500 | 1240 | 2050 | 0.55*2 | 16800 | 1.5 | 45 | DN80 | DN40 | DN25 | 730 | 1650 |

HBW-12B | 2860 | 2500 | 1240 | 2180 | 1.1*2 | 26000 | 1.5 | 45 | DN80 | DN40 | DN25 | 830 | 1760 |

HBW-12C | 2860 | 2500 | 1240 | 2420 | 1.1*2 | 26000 | 1.5 | 45 | DN100 | DN40 | DN25 | 1050 | 2030 |

HBW-15A | 2860 | 2500 | 1520 | 2440 | 1.5*2 | 36400 | 2.2 | 60 | DN100 | DN40 | DN25 | 1280 | 2500 |

HBW-15B | 2860 | 2500 | 1520 | 2630 | 1.5*2 | 36400 | 2.2 | 60 | DN100 | DN40 | DN25 | 1370 | 2660 |

HBW-17A | 3200 | 2750 | 1760 | 2630 | 1.1*4 | 52000 | 2.2 | 60 | DN80*4 | DN40 | DN25 | 1820 | 3460 |

HBW-21B | 3200 | 2750 | 2120 | 2750 | 1.5*4 | 72800 | 2.2 | 114 | DN80*4 | DN40 | DN25 | 2050 | 4000 |

HBW-21C | 3200 | 2750 | 2120 | 2750 | 1.5*4 | 72800 | 2.2 | 114 | DN80*4 | DN40 | DN25 | 2150 | 4050 |

HBW-21D | 3550 | 3100 | 2120 | 2750 | 1.5*4 | 72800 | 2.2 | 114 | DN80*4 | DN40 | DN25 | 2330 | 4710 |

HBW-21E | 4150 | 3700 | 2120 | 2870 | 1.5*6 | 109200 | 2.2 | 114 | DN80*4 | DN40 | DN25 | 2650 | 5550 |

HBW-21F | 4750 | 4300 | 2120 | 2970 | 1.5*8 | 145600 | 3.7 | 140 | DN80*4 | DN40 | DN25 | 3100 | 6500 |

HBW-21G | 5050 | 4600 | 2120 | 3120 | 1.5*8 | 145600 | 3.7 | 140 | DN80*4 | DN40 | DN25 | 3500 | 7480 |

HBW-21H | 5480 | 5000 | 2120 | 3120 | 1.5*8 | 145600 | 5.5 | 160 | DN100*4 | DN40 | DN25 | 3800 | 8240 |

HBW-26A | 5080 | 4600 | 2620 | 3120 | 1.5*8 | 145600 | 5.5 | 160 | DN100*4 | DN40 | DN25 | 4800 | 9170 |

HBW-26B | 5480 | 5000 | 2620 | 3220 | 1.5*8 | 145600 | 5.5 | 160 | DN100*4 | DN40 | DN25 | 5600 | 11300 |

HBW-26C | 6230 | 5750 | 2620 | 3220 | 1.5*10 | 182000 | 7.5 | 240 | DN100*4 | DN40 | DN25 | 6000 | 12560 |

Remarks:

1.Design conditions: Inlet temperature t1=37℃, outlet temperature t2=32℃, wet bulb temperature t=28℃, dry bulb temperature O=31.5℃, barometric pressure P=9.94×104Pa

2.The water tank should ensure that there is enough water, so that the water at the bottom of the tank can be higher than the pump inlet and filter screen when the system is running, and the general water level is > 300mm

3.The above technical parameters are for reference only. Our company reserves the right to modify the product appearance and technical parameters due to the continuous upgrading of technology

Copyright © 2019 Jiangsu Huatal Cooling Technology Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.