Jiangsu Huatal Cooling Technology., Ltd.

Complimentary Samples For You And Technical Consultation At Your Convenience

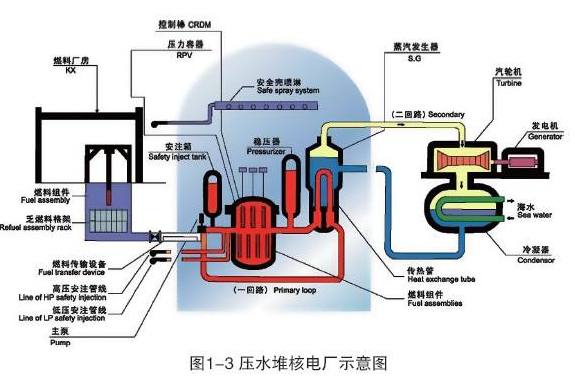

The three circuits of PWR nuclear power plant can be classified into the following three types: the cooling medium in the primary circuit is generally called coolant or moderator (moderated neutron), which is pressurized light water (ordinary water), which is radioactive due to contact with the reactor core; In the secondary circuit of cooling water and the role of common coal-fired power plant, heat into steam power generation, there is no radioactive; The water discharged in the third circuit is usually filtered sea water and cooled in the second circuit before being discharged back to the coast or river. The discharged water does not contain radioactivity, but there is thermal pollution in the relative discharge environment due to the excessive heat discharged in the second circuit. Pressurized water reactors use light water as coolant and moderator. It is mainly composed of nuclear steam supply system (primary circuit system), turbo generator system (secondary circuit system) and other auxiliary systems. After the coolant absorbs the heat energy released by nuclear fuel fission in the reactor core, it passes the heat through the steam generator to the second circuit to generate steam, and then enters the steam turbine to work and drive the generator to generate electricity.

Primary loop system of PWR nuclear power plant: the primary loop system of PWR nuclear power plant is completely separated from the secondary loop system. It is a closed loop system. The plant's principle flow: the main pump into the reactor high pressure coolant, coolant generally maintained at 120 ~ 160 atmospheres. Under high pressure, the coolant will not vaporize even if the temperature is more than 300℃. The coolant takes the heat energy from the nuclear fuel out of the reactor and into the steam generator. It passes through thousands of heat pipes and transmits the heat to the secondary loop water outside the pipe, making the water boil and produce steam. The coolant passes through the steam generator and is fed into the reactor by the main pump, which circulates back and forth, constantly taking heat out of the reactor and converting it to produce steam. The high temperature and high pressure steam from the steam generator drives the steam turbine generator to generate electricity. The waste steam that has done the work condenses into water in the condenser, and is fed to the heater by the condensing feed pump, which is then reheated and returned to the steam generator. This is a two loop circulatory system. The condenser USES the river water pumped by the three-loop circulating pump as coolant, which is discharged back into the river after cooling to form the third loop circulation.

Pressure reactor is the core component of nuclear power plant: pressurized water reactor is composed of pressure vessel and reactor core. Pressure vessel is a sealed, thick and heavy, up to tens of meters of cylindrical steel shell, the steel used high temperature and high pressure resistance, corrosion resistance, used to drive the steam turbine rotation of high temperature and high pressure steam is generated here. A control rod drive mechanism is arranged on the top of the container to drive the control rod up and down in the core. The core is the heart of the reactor, housed in the middle of a pressure vessel. It's made of fuel assemblies. Like the coal fired by boilers, fuel pellets are the basic unit of combustion for nuclear power plants' atomic boilers. The pellets are sintered from uranium dioxide and contain 2 to 4 percent uranium-235 in a small cylindrical form with a diameter of 9.3 mm. The pellet is placed in a zirconium clad tube with both ends sealed to form a fuel element rod approximately 4 meters long and 10 millimeters in diameter. In addition, the reactor core has control rods and boron-containing cooling water (coolant). The rods, made of silver indium and cadmium and encased in stainless steel, absorb neutrons from the reactor and are about the size of the fuel rods. Multiple control rods are formed into bunches to control the speed of nuclear reaction in the reactor. If the reactor fails, insert enough control rods into the core immediately and the reactor will stop working in a short time, which ensures the safety of the operation of the reactor.

Because of its high power density, compact structure, safety and easy control, mature technology, low cost and low generation cost, PWR nuclear power plant has become the most widely used commercial nuclear power reactor in the world, accounting for 3/4 of the total number of light-water reactor nuclear power units. China's nuclear power plants and submarines have basically adopted advanced pressurized water reactor nuclear power units, the safety is much higher than fukushima. In the 1990s, the United States and advanced European nuclear power countries set a series of specific goals for the safety, technology and economy of nuclear power plants to be built in the future. Countries are also developing third-generation pressurized water reactors that meet these requirements. Some of them are represented by EPR, a European power reactor jointly developed by France and Germany, and AP1000 developed by Westinghouse. EPR proposes to adopt a common safety method in the design of future PWR, to improve the safety by reducing the probability of core melting and serious accidents and improving the containment capacity, and to fundamentally improve the operating conditions in terms of radioactive protection, waste treatment, maintenance improvement and reduction of human error. The AP1000 features a fully passive safety system, simplified design and layout, and modular construction. In the future, nuclear reactors will pay more attention to safety and energy saving. The design of the third and fourth generation nuclear reactors in China will adopt more pure cooling water as the cooling medium of the condenser. In the future, the closed cooling tower equipment will be more and more widely used in nuclear power plants.

Copyright © 2019 Jiangsu Huatal Cooling Technology Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.