Jiangsu Huatal Cooling Technology., Ltd.

Complimentary Samples For You And Technical Consultation At Your Convenience

Recently, HuaTal Group supplied 6 sets of HBW counter flow closed cooling tower to a domestic new metal material manufacturer, for cutting fluid cooling. Cutting fluid is a semi-synthetic processing liquid product containing mineral oil. It has the most advanced formulation technology and is especially suitable for large aluminum casting manufacturers. It not only effectively prevent the workpiece from rust or chemical corrosion, but also effectively prevent bacterial erosion and infection.

The HBW counter flow closed cooling tower we supplier has the following advantages:

Adopts imported Magnesium-Aluminum-Zinc alloy plating steel sheet as outer plate, it has outstanding anti-corrosion effect, and its service life is 10-20 times that of galvanized steel sheet. The coating on the surface has fluidity and notch protection performance (self-healing);

Counter flow type cooling, less heat dissipation blind area, high heat exchange efficiency;

High efficiency water condenser, operation water drift rate ≤0.001%;

The coil pipe adopts anti-freeze, energy-saving design, to ensure the circulation water can be completely drained to avoid freezing damage during non operation period of winter season;

The unit design is elegant, automatic digital display, easy to operate and maintain;

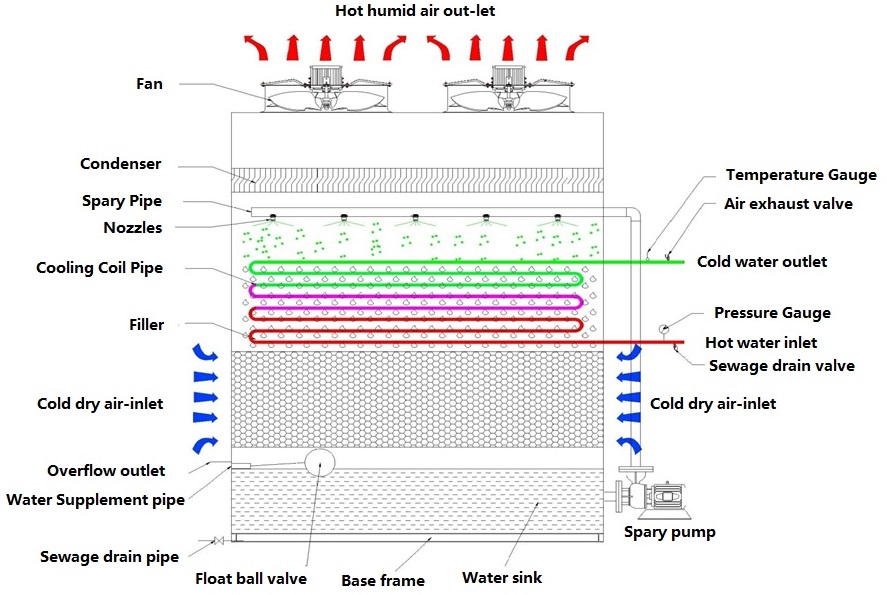

Here's how it works:

Internal water circulation system: After the internal circulating water get cooled in the coil pipe, it will flow to the heat source (equipments need cooling) by the circulating water pump. After heat exchange, the circulating water heated up and back to the coil pipe for cooling.

External water circulation system: To achieve the purpose of cooling the coil pipe, the external sparied water did heat exchange by contacting with the coil pipe and the fills, then falls into the lower water sink, the spray pump then send the water back to the top of closed cooling tower for circulation again.

The internal circulating water did heat exchange with the external spray water and air by contacting the coil pipe, so the process avoiding the water pollution caused by the direct contact with external water and air. Since the external circulating water is pre-cooled by PVC fills, the heat transfer effect is more efficent. Compared with the open cooling tower, its structure features and electric control function realized more water saving effects.

HuaTal Group has been committed to becoming a world-class cooling system and service supplier. We will provide our closed cooling tower and cooling solution services to the customer all over the world.

Copyright © 2019 Jiangsu Huatal Cooling Technology Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.