Jiangsu Huatal Cooling Technology., Ltd.

Complimentary Samples For You And Technical Consultation At Your Convenience

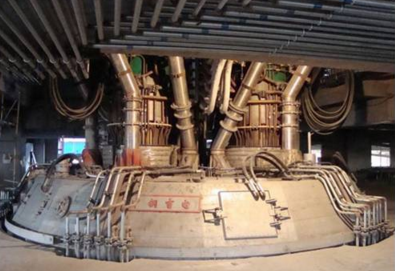

Main production process of calcium carbide furnace are aerobic heating method and electric heating method. Generally, calcium carbide is produced by electric heating method, which is, quicklime and carbonaceous raw materials (coke, anthracite or petroleum coke) are produced in the calcium carbide furnace by arc high-temperature melting reaction.

In one of our projects in Inner Mongolia province, during the transformation process of the calcium carbide furnace cooling system, we found that the scaling phenomenon of water-cooling jacket was quite serious. The main reason for the damage of the cover system of calcium carbide furnace is the hard scale and dirt brought into the equipment by cooled circulating water. Especially for calcium carbide furnaces which uses blue carbon as the raw material, the surface temperature is as high as 800 degrees, and the surface equipment is water-jacket with low water flow rate. The hardness and dirt brought into the equipment by open circulation cooled water are deposited in the equipment, which is the main cause of equipment damage in the furnace. Therefore, high requirements for cooling water quality are required. At present, the open cooling water system adopted can hardly meet the water quality requirements. Serious equipment burning, low operating rate of calcium carbide furnace and high maintenance cost are common problems in this system. At the same time, because of the leakage of the equipment, the operation of calcium carbide furnace to form a safety hazard.

After receiving the customer's call, we immediately organized a engineer team to visit the site and determine the transformation plan. We design the calcium carbide furnace circulating water from the open cooling to closed cooling tower circulation system. The cooling efficiency almost doubled, but with less than half of the circulating water volume, saving at least $20,000 investment in pumps and pipelines. Because of the close loop water circuilation, an 80 square meter water pool was cancelled, and $10,000 investment was saved. At the same time, the water pressure formed by the 28m height difference of the calcium carbide furnace, we reduce the operating power of the system by 50%, and the annual water pump electricity cost of one furnace is reduced by $50,000. The operating rate of calcium carbide furnace increased by 2%, and the annual benefit was $60,000. Due to the reduction of damage to the cover and nozzle, the annual maintenance cost is also saved more than $50,000 yuan. So in generally, our closed cooling system help the factory to save $130,000 of annual operation cost, and increased $60,000 benifits.

The closed cooling system eliminates the corrosion problem caused by dissolved oxygen to the equipment, eliminates the damage caused by the hard scale in the water and the dirt in the atmosphere, and prolongs the service life of the equipment.The circulating water system adopts green environmental protection design and water balance design, without chemical water pollution and waste water discharge, and is all managed and monitored by computers. The system directly monitors the leakage fault of calcium carbide furnace equipment with the change of liquid level curve, which ensures the safe operation of calcium carbide furnace system.

Copyright © 2019 Jiangsu Huatal Cooling Technology Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.