Jiangsu Huatal Cooling Technology., Ltd.

Complimentary Samples For You And Technical Consultation At Your Convenience

Can the cooling tower not produce white fog when it is running in winter?

A closed cooling tower is a device that exchanges heat through heat transfer. When it is running in winter, due to the low ambient temperature, when the gas is discharged from the outside of the tower, the gas temperature will be lower than the dew point temperature, which is easy to produce white fog. As the people's requirements for environmental protection are getting higher and higher, it is required that the cooling tower should not produce white fog when it is running in winter.

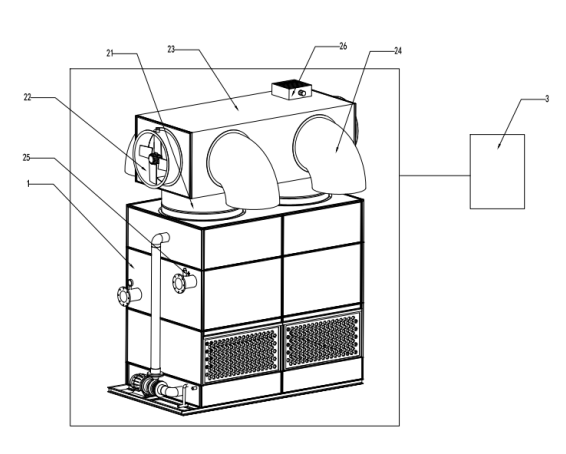

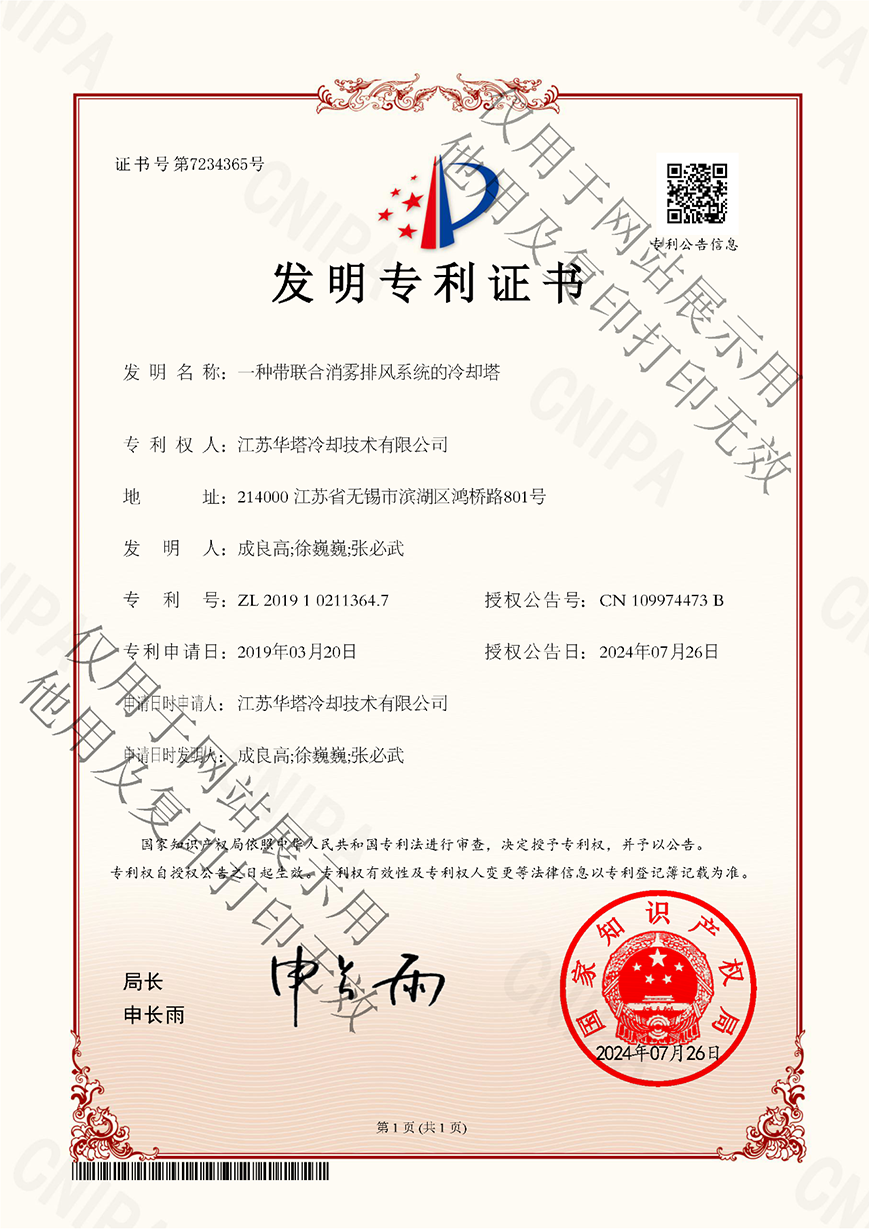

After many tests, Jiangsu Huata has developed a cooling tower with a combined dew removal and exhaust system, thereby overcoming the defects in the above-mentioned prior art and obtaining a patent.

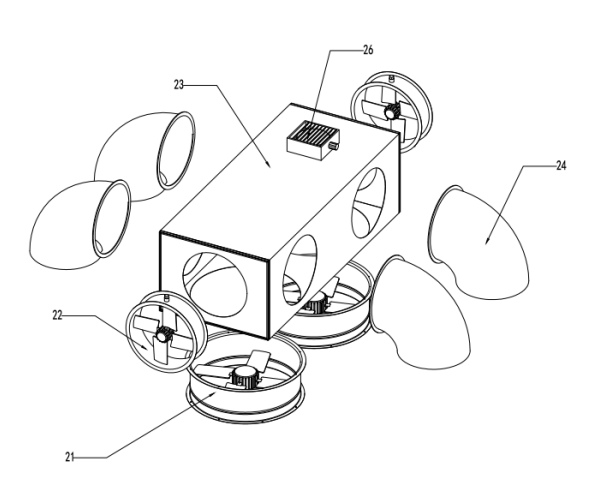

The water vapor fogging point is 0℃ temperature and 100% humidity. When the external environment temperature is higher than 0℃, the hot and humid air in the cooling tower needs to be cooled by the hot air main fan 21 before being discharged. At this time, the discharge will not produce white fog; when the external environment temperature is lower than 0℃ and the humidity of the hot and humid air in the cooling tower is less than 80%, it has not reached the level of fogging and frosting. Because the external environment temperature is low, it is only necessary to turn on the cold air auxiliary fan 22 to discharge the hot and humid air in the cooling tower (it is wasteful to turn on the hot air main fan 21 at this time); when the external temperature is lower than 0℃ and the humidity of the hot and humid air in the cooling tower is greater than 80%, when the humidity of the hot and humid air is slightly higher, the water vapor is easy to reach the fogging and frosting point. At this time, the hot air main fan 21 is turned on, and the cold air auxiliary fan 22 is turned on and reversed to mix the hot and humid air generated by the cooling tower with the dry and cold air of the external environment, so that the humidity of the hot and humid air in the cooling tower can be reduced to below 80%, and then no white fog will be generated when it is discharged from the induced draft duct 24.

The opening and closing of the hot air main fan 21 and the cold air auxiliary fan 22 are mainly connected to the electrical appliances of the combined defogging and exhaust system 2 of the cooling tower through the PLC controller 3. After the temperature sensor 25 and the humidity sensor 26 transmit the electrical signals to the PLC controller 3, the PLC controller 3 converts the electrical signals into mechanical signals of the hot air main fan 21 and the cold air auxiliary fan 22, thereby realizing the opening and closing of the hot air main fan 21 and the cold air auxiliary fan 22.

The cooling tower is equipped with a combined defogging and exhaust system 2, and the operation of the combined defogging and exhaust system 2 is controlled by the PLC controller 3. On the one hand, even in the cold winter, when the humidity of the outside air is high, the combined action of the hot air main fan 21 and the cold air auxiliary fan 22 can also avoid the phenomenon of white dew in the cooling tower, and the operation is more environmentally friendly. On the other hand, when the outside temperature is low and the humidity of the hot and humid air in the tower is not high, the cold air auxiliary fan 22 can be turned on for exhaust, which is energy-saving and environmentally friendly: the induced draft duct 24 is a shaped structure and the air outlet is downward, which is more conducive to the discharge of the gas generated by the cooling tower.

Copyright © 2019 Jiangsu Huatal Cooling Technology Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.